Metall- und Materialverarbeitung – Häufig gestellte Fragen

Can the increased temperature variability in my annealing furnace be causing the ductility variations in my product?

It depends on the amount and location of the variability. Variability in the critical annealing parameters—temperature, dew point and atmosphere compositions—can have a dramatic impact on product quality. To help find the source of the variability, record the critical process parameters during production—larger than normal deviations in temperature can affect grain growth, hardness and ductility. Then you can correlate poor quality runs to data trends and identify what may be causing the change in properties.

Installing a process control system to monitor and control these variables can help you reduce variability. A small investment in control technology can provide a large return in reduced production costs and improved quality. Our commercial engineers and extensive experience in process controls can help you improve your process consistency and save money.

How can I increase production flexibility and ensure the quality of my annealed components?

Carbon steel components have been routinely annealed or heat treated in nitrogen-hydrogen based atmospheres to relieve stress, alter microstructure and/or improve surface appearance for a number of years. The flow rate and composition of the atmosphere to be used for annealing components in furnaces are usually determined by a trial and error approach.

Although the composition of nitrogen-hydrogen based atmosphere introduced into a furnace does not change with time, the true reducing or oxidiing potential of the atmosphere inside the furnace changes continuously with time due to leaks and drafts in the furnace, desorption of impurities such as moisture from the surface of components or decomposition of lubricant present on the surface of components being annealed.

What causes discoloration and oxidation of stainless steels in brazing, sintering or annealing processes?

All grades of stainless steels are iron-based alloys with significant percentages of chromium. Typically, stainless steels contain less than 30% chromium and more than 50% iron. Their stainless characteristics stem from the formation of an invisible, adherent, protective and self-healing chromium-rich oxide (Cr₂O₃) surface film. While stainless steels are resistant to rusting at room temperatures, they're prone to discoloration by oxidation at elevated temperatures due to the presence of chromium and other alloying elements such as titanium and molybdenum.

Factors that contribute to increased oxidation include high dew points, high oxygen and oxides of lead, boron, and nitrides on the surface. For bright stainless steels, depending on composition, process them in a highly reducing atmosphere with a dew point lower than –40°C and a minimum of 25% hydrogen.

What causes stainless steel to turn green in a continuous belt furnace?

The green color that you see on stainless steel parts is chromium oxide (Cr₂O₃). It forms when there is too much oxygen and/or moisture in the furnace atmosphere, which is usually caused by a water leak, poor atmosphere tightness, or overly low flow rates of atmosphere gas. A dark green-brown color indicates significant levels of free oxygen inside the furnace originated by a large air leakage.

In addition to the traditional steel and copper test, some companies run a piece of stainless through the furnace to check for high moisture and oxygen levels. A better and more precise way of measuring moisture and oxygen levels is to install an oxygen analyzer and dew point meter. It's inexpensive and highly accurate. If a green oxide film is forming on your stainless steel parts, that's an indication that the furnace or atmosphere is not optimized.

What is dezincification and how does it apply to thermal processing of brass?

Dezincification is typically defined as the leaching of zinc from copper alloys in an aqueous solution. In thermal processing of brasses (and other zinc-containing alloys), dezincification is the removal of zinc from the metal substrate during thermal processes, like brazing and annealing, typically due to the very low vapor pressure of zinc in the alloys. Dezincification can result in excessive furnace dusting, zinc vapors alloying with other metals, and in extreme cases, loss of alloy properties.

While eliminating dezincification is not always possible, it can be reduced during thermal processing. Controlling temperature, time at temperature, and the furnace atmosphere's reducing potential can help minimize dezincification and improve your thermal processing. However, understanding which variables to change can be a challenge. Air Products' industry specialists, experienced in thermal processing, can help pinpoint the variable(s) that you can regulate to help lower costs and improve productivity by minimizing dezincification.

What’s the best approach to select the hydrogen concentration for our nitrogen-hydrogen atmosphere for bright annealing of steels?

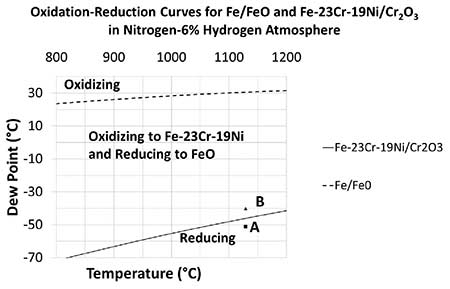

Bright annealing of steels requires conditions that are reducing to steel oxides. Traditionally, the Ellingham diagram has been used to predict the conditions that correspond to oxidation of pure metals or reduction of their oxides. This method can be used to predict the conditions that should be reducing to iron oxides and the oxides of the alloying elements added to steels, such as chromium oxide when stainless steels are considered. This traditional approach is not precise because it only uses thermodynamic data for pure metals and their oxides—it ignores the fact that iron and alloying elements form a solid solution. In addition, you can only determine the approximate equilibrium partial pressure ratio of hydrogen and water vapor for oxidation of a specific metal at a particular temperature.

Alternatively, you can use more accurate and convenient diagrams for steels and other alloys, which are created with the help of modern databases and computer programs, such as FactSage™ (thermochemical software and database package developed jointly between Thermfact/CRCT and GTT-Technologies) or Thermo-Calc software. Using the oxidation-reduction curves, presented as dew point of pure hydrogen or nitrogen-hydrogen atmospheres versus temperature, you can quickly select the atmosphere for annealing steels without formation of oxides. The diagram in Figure 1 was calculated using FactSage. This diagram shows that oxidation-reduction curves for Fe-18%Cr and Fe-18%Cr-8%Ni systems representing stainless steels are higher than the corresponding Cr/Cr₂O₃ curves. For alloys (e.g. steels), you can achieve more precise calculations using thermodynamic data from both the pure substances (i.e. pure metals and oxides) and solutions databases. Such diagrams can be produced specifically for the steels of interest and variety of atmosphere compositions.

These methods can help you troubleshoot and optimize your annealing operation by balancing hydrogen usage versus product quality.

Figure 1: